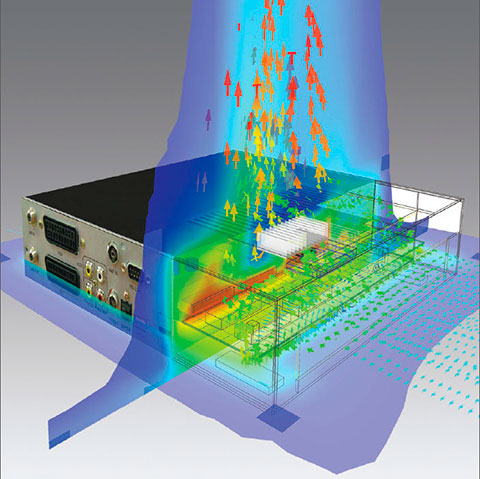

FloTHERM is powerful 3D simulation software for thermal design of electronic components and systems. It enables engineers to create virtual models of electronic equipment, perform thermal analysis and test design modifications quickly and easily in the early stages of design process well before any physical prototypes are built. FloTHERM uses advanced CFD (computational fluid dynamics) techniques to predict airflow, temperature and heat transfer in components, boards and complete systems.

FloTHERM is an industry-specific analysis tool specially designed for a wide range of electronic applications that include:

- Computers and data processing

- Telecommunications equipment and network systems

- Semiconductor devices, IC’s and components

- Aerospace and defense systems

- Automotive and transportation systems

- Consumer electronics

FloTHERM features specialization, built-in intelligence and automation not found in traditional analysis software. This functionality maximizes productivity for thermal design experts, minimizes the learning curve for mechanical design engineers and provides the highest levels of return on investment available from analysis software. In a small to medium-sized company, FloTHERM can pay for itself several times over in just one year and even faster as the size of the company increases. Experience the benefits of using FloTHERM for thermal design of electronics that include:

- Solving thermal problems before hardware is built.

- Reducing design re-spins and product unit costs.

- Significantly reducing time to market.

FloTHERM is having the following add on modules:

1.FloTHERM PCB:

FloTHERM PCB is a unique, software program for streamlining concept development of printed-circuit boards (PCBs), while ensuring good thermal design and accelerating the PCB design process. FloTHERM PCB facilitates collaboration between Product Marketing,Electronic Engineers and Mechanical Engineers on PCB design, particularly during the conceptual phase of the design process.

FloTHERM PCB serves as a common platform that Electrical Engineers and Mechanical Engineers can use to collaboratively create and thermally evaluate multiple proposed board layouts quickly and accurately.

2.FloTHERM IC:

FloTHERM IC is a software product from Mentor Graphics that incorporates a high level of automation for key tasks related to Semi-conductor thermal characterization and design. An intuitive wizard-driven user interface, interoperability with package-level EDA tools, and enterprise-level data scalability and portability are the other key features of FloTHERM IC.

Built around FloTHERM® PACK, the well-established package Smartpart technology, and the industry leader FloTHERM’s CFD solver technology, FloTHERM IC greatly boosts productivity thermal analysis in the Semi-conductor industry.

3.FLOPACK:

FloTHERM PACK (www.flothermpack.com) is a web-based software program which produces reliable, accurate thermal models of IC packages and associated parts with the minimum of effort. Designed to fulfil the industries need for a rapid response to innovations in packaging design, FloTHERM PACK is a web-based application that contains a parametrically-driven menu for each part type. To take advantage of FloTHERM PACK, you use your standard web browser to enter data describing the IC package you want to use. For example, if you want to build a model of a ball grid array (BGA) package, the typical data entry items would include: number of balls, substrate conductivity, die size, and substrate metal layer thickness and coverage. If you don’t have detailed information about the internal geometry of yourpart, the JEDEC Library SmartPart wizard in FloTHERM PACK lets you create”best guess” thermal models quickly and easily. All you need to do is answer three or four questions about your component. Utilizing built-in intelligent rules based on common industry design practices, the SmartPart wizard.